Nov 17, 2025

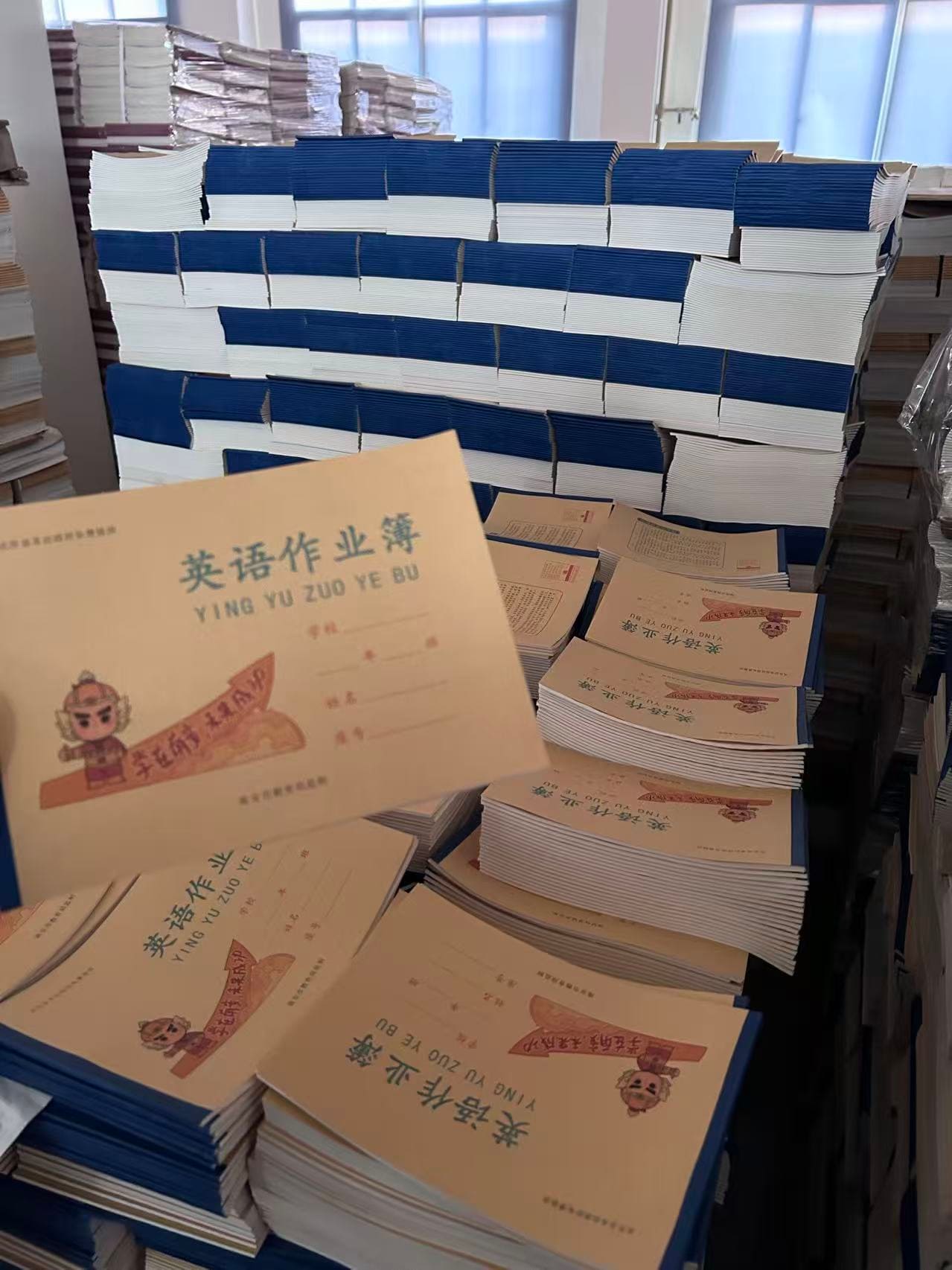

As a professional printing manufacturer equipped with advanced flexographic and offset printing lines, we not only specialize in adhesive labels and packaging boxes — we also provide custom notebook printing for brands, companies, schools, gift suppliers, and promotional product distributors.

Whether you need notebooks for retail, corporate gifts, marketing events, or internal office use, we offer a complete one-stop solution from material selection to finishing effects.

Fully Customizable Notebook Options

We produce a wide range of notebook styles tailored to your needs:

Softcover notebooks

Hardcover notebooks

Saddle-stitched booklets

Spiral or wire-bound notebooks

Notepads and tear-off pads

Branded corporate notebooks

Student exercise books

Premium gift notebooks

You can customize every detail to match your brand identity or design requirements.

Material & Printing Options

We offer high-quality papers and multiple printing processes:

Cover materials: art paper, kraft paper, specialty paper, coated paper, soft-touch paper

Inner pages: 70–120gsm woodfree paper, dotted pages, ruled lines, blank pages, custom layouts

Printing techniques: offset printing, spot color printing, Pantone matching

Finishes: matte/gloss lamination, hot stamping, embossing, debossing, spot UV, foil edging

Binding: saddle stitch, glue binding, spiral, wire-O, hardcover case binding

These options give you complete creative freedom for both functionality and visual appeal.

Why Choose Us for Notebook Printing?

1. Professional Production Lines

Our factory uses advanced printing equipment capable of producing large volumes with consistent color accuracy and stability.

2. Flexible Order Quantities

We support both small batch sampling and mass production runs, allowing you to test the market before scaling.

3. Custom Branding & Premium Gift Quality

Make your brand stand out with personalized covers, company logos, and high-end finishing options.

4. Global Shipping Support

We provide secure packaging and coordinate delivery to customers worldwide.

Perfect for Multiple Applications

Our custom notebooks are ideal for:

Brand promotions

Corporate gifts

Retail stationery products

School supplies

Trade shows & events

Hotel & hospitality gifts

Workshops and training materials

No matter your industry, we can turn your design into a high-quality printed notebook.

Contact Us

Looking to create your own customized notebooks?

Our team is ready to support you with professional suggestions, samples, and fast quotation.